Alloy Analysis for QA/QC at Fabricators

An XRF Alloy Analyzer in your machine shop or fabrication facility provides you with the essential information that the proper alloy is being used in the manufacturing process. You have committed to manufacture goods in conformance with your customers specifications, giving rise to the need for analysis of incoming materials, finished product, and everything in between. This requires ongoing vigilance and a well documented QA/QC procedure. Material mix-ups can occur at any stage of the process, from incoming material inspection to machining stations to final assembly and shipment.

Please contact our experts to understand how handheld XRF can greatly improve your QA/QC program.

Rather than relying on Material Test Reports (MTR) –which do not provide 100% certainty – a handheld XRF alloy analyzer allows the inspectors to make instant checks that the alloy is the proper material. This can prevent the investment of a large amount of time in machining a part of the wrong alloy, and it can provide final verification of the alloys prior to shipment to your customers.

Many customers are now requiring complete Positive Material Identification (PMI), especially of their critical manufacturing components. A handheld XRF analyzer will provide the analysis required, and the data storage and report generation capabilities of S1 TITAN SP handheld XRF analyzers for fabricators provide a fast and easy-to-use system for the entire measurement and reporting cycle.

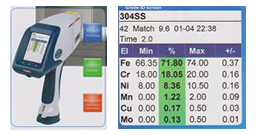

Handheld PMI S1 Titan SP available up to 500 oC temperature of Sample/Part

Element display with match no

match and type material identification

Positive Material Identification (PMI) for Your Plant Safety

Positive Material Identification (PMI) is an important part of your safety program. PMI ensures that the specified alloy is used for every component of the pressure vessel or plant being constructed. Parts made of the wrong alloy can corrode or wear more rapidly than expected when placed in service. Portable X-ray Fluorescence (XRF) analysis in plants and refineries can help you avoid catastrophic failures caused by these improper parts. Please contact our experts to understand how our analyzers will improve the safety of your plant.

Identification of alloy classes

In many fields, the use of portable XRF analyzers (XRF guns) to ensure 100% on-site PMI is a straight-forward procedure and considered standard practice. Handheld XRF PMI guns provide rapid and completely nondestructive alloy identification of all alloy classes including:

- Carbon & Low Alloy Steel

- Stainless Steel

- Nickel and High Temperature alloys

- Copper alloys

- Titanium alloys

- Aluminum alloys

These PMI XRF analyzers can analyze any shape parts within your system – plates, pipes, flanges, welds, valves and other components – for complete PMI. The large library (grade definitions) provided with the analyzer includes most common grades used in refineries and other production environments. If the specific grade you require is not defined within this library, or your naming convention is different from that used on the analyzer, the library can easily be customized to provide the exact definition and name used in your environment.

Whether you are using company inspection procedures or API RP 578, recording of the data and printing of reports could not be easier. S1 Titan SP analyzers store all the data acquired in an easy to use format which can be directly imported into Microsoft Excel® or formatted and printed using the optional report generator. Handheld PMI S1 Titan SP available up to 500 oC temperature of Sample/Part

PMI Test application at site